bubuka produk:

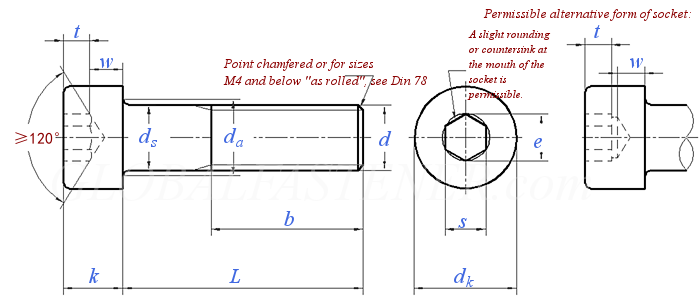

Stainless Steel Sagi genep stop kontak Kepala Cap Bolts (DIN 912) mangrupakeun cylindrical - fasteners sirah jeung sockets hex internal. Dijieun tina sasmita stainless steel kawas SS201 (anggaran - ramah pikeun lingkungan garing), SS304 (sadayana - lalawanan korosi buleud pikeun pamakéan umum), sarta SS316 (asam jeung saltwater lalawanan pikeun laut / widang kimia), aranjeunna nawiskeun kakuatan tinggi na kontrol torsi tepat via hex wrenches. Luyu sareng standar DIN 912, ukuranana ti M3 dugi ka M36 sareng panjangna ti 10mm dugi ka 300mm. Loba dipaké dina mesin (die fixturing), éléktronika (circuit board mounts), otomotif (komponén mesin), jeung alat precision, low-profil sirah maranéhanana cocog kana instalasi spasi ketat.

Parentah pikeun pamakéan:

Pasang nganggo rengkuh stop kontak hex anu cocog, kencangkeun kana torsi anu disarankeun (hindari over- tightening pikeun nyegah karusakan benang)

1.SS304/316 bolts: Ngabersihan rutin pikeun ngawétkeun lapisan oksida (euweuh perlakuan anti karat diperlukeun).

2.SS201 bolts: Hindarkeun lingkungan beueus; usap garing lamun kakeunaan.

3. Pariksa sirah na threads pikeun maké - ngaganti bolts lamun cacad atawa dilucuti.

| Ukuran Thread | M1.4 | M2 | M3 | M8 | M10 | M12 | (M14) | M16 | (M18) | ||||

| d | |||||||||||||

| P | Pitch | Benang kasar | 0.3 | 0.4 | 0.5 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | ||

| Fine thread pitch-1 | - | - | - | 1 | 1.25 | 1.25 | 1.5 | 1.5 | 1.5 | ||||

| Fine thread pitch-2 | - | - | - | - | 1 | 1.5 | - | - | 2 | ||||

| dk | sirah polos | max | 2.6 | 3.8 | 5.5 | 13 | 16 | 18 | 21 | 24 | 27 | ||

| sirah kurled | max | 2.74 | 3.98 | 5.68 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | |||

| min | 2.46 | 3.62 | 5.32 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | ||||

| da | max | 1.8 | 2.6 | 3.6 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 20.2 | |||

| ds | max | 1.4 | 2 | 3 | 8 | 10 | 12 | 14 | 16 | 18 | |||

| min | 1.26 | 1.86 | 2.86 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | ||||

| e | min | 1.5 | 1.73 | 2.87 | 6.86 | 9.15 | 11.43 | 13.72 | 16 | 16 | |||

| k | max | 1.4 | 2 | 3 | 8 | 10 | 12 | 14 | 16 | 18 | |||

| min | 1.26 | 1.86 | 2.86 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | ||||

| s | Ukuran Nominal | 1.3 | 1.5 | 2.5 | 6 | 8 | 10 | 12 | 14 | 14 | |||

| min | 1.32 | 1.52 | 2.52 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | ||||

| max | 1.36 | 1.56 | 2.58 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | ||||

| t | min | 0.6 | 1 | 1.3 | 4 | 5 | 6 | 7 | 8 | 9 | |||

| w | min | 0.5 | 0.55 | 1.15 | 3 | 4 | 4.8 | 5.8 | 6.8 | 7.8 | |||

| Beurat per 1000 produk baja (≈kg) | - | - | - | - | - | - | - | - | - | ||||

| Panjang Utas b | - | - | - | - | - | - | - | - | - | ||||

| Ukuran Thread | (M22) | (M27) | (M33) | M56 | M64 | M72 | M80 | M90 | M100 | ||||

| d | |||||||||||||

| P | Pitch | Benang kasar | 2.5 | 3 | 3.5 | 5.5 | 6 | 6 | 6 | 6 | 6 | ||

| Fine thread pitch-1 | 1.5 | 2 | 2 | 4 | 4 | 4 | 4 | 4 | 4 | ||||

| Fine thread pitch-2 | 2 | - | - | - | - | - | - | - | - | ||||

| dk | sirah polos | max | 33 | 40 | 50 | 84 | 96 | 108 | 120 | 135 | 150 | ||

| sirah kurled | max | 33.39 | 40.39 | 50.39 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |||

| min | 32.61 | 39.61 | 49.61 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | ||||

| da | max | 24.4 | 30.4 | 36.4 | 63 | 71 | 79 | 87 | 97 | 107 | |||

| ds | max | 22 | 27 | 33 | 56 | 64 | 72 | 80 | 90 | 100 | |||

| min | 21.67 | 26.67 | 32.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | ||||

| e | min | 19.44 | 21.73 | 27.43 | 46.83 | 52.53 | 62.81 | 74.21 | 85.61 | 97.04 | |||

| k | max | 22 | 27 | 33 | 56 | 64 | 72 | 80 | 90 | 100 | |||

| min | 21.48 | 26.48 | 32.38 | 55.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | ||||

| s | Ukuran Nominal | 17 | 19 | 24 | 41 | 46 | 55 | 65 | 75 | 85 | |||

| min | 17.05 | 19.065 | 24.065 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | ||||

| max | 17.23 | 19.275 | 24.275 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | ||||

| t | min | 11 | 13.5 | 18 | 34 | 38 | 43 | 48 | 54 | 60 | |||

| w | min | 9.4 | 11.9 | 13.5 | 19 | 22 | 25 | 27 | 32 | 34 | |||

| Beurat per 1000 produk baja (≈kg) | - | - | - | - | - | - | - | - | - | ||||

| Panjang Utas b | - | - | - | - | - | - | - | - | - | ||||

Hebei Duojia Metal Products Co., Ltd. baheulana katelah Yonghong Expansion Screw Factory. Cai mibanda leuwih 25 taun pangalaman profésional dina fasteners manufaktur. Pabrik lokasina di Cina Standar Room Industrial Base - Yongnan District, Handan Kota. Éta ngalaksanakeun produksi online sareng offline sareng manufaktur fasteners ogé bisnis jasa penjualan hiji-eureun.

Pabrik nyertakeun wewengkon leuwih 5.000 méter pasagi, sarta gudang nyertakeun wewengkon leuwih 2.000 méter pasagi. Taun 2022, perusahaan ngalaksanakeun paningkatan industri, standarisasi tatanan produksi pabrik, ningkatkeun kapasitas neundeun, ningkatkeun kapasitas produksi kaamanan, sareng ngalaksanakeun ukuran perlindungan lingkungan. Pabrik parantos ngahontal lingkungan produksi héjo awal sareng ramah lingkungan.

Pausahaan gaduh mesin pencét tiis, mesin stamping, mesin ngetok, mesin threading, mesin ngabentuk, mesin spring, mesin crimping, sarta robot las. Produk utamana nyaéta runtuyan screws ékspansi katelah "panjat tembok".

Ogé ngahasilkeun produk hook ngawangun husus kayaning kai las huntu domba screws ring panon jeung mesin huntu domba bolts ring panon. Sajaba ti éta, parusahaan geus dimekarkeun jenis produk anyar ti tungtung 2024. Ieu museurkeun kana produk pre-dikubur pikeun industri konstruksi.

Pausahaan ngabogaan tim jualan profésional sarta tim nurutan-up profésional pikeun safeguard produk Anjeun. Pausahaan ngajamin kualitas produk anu ditawarkeunana sareng tiasa ngalaksanakeun pamariksaan dina sasmita. Upami aya masalah, perusahaan tiasa nyayogikeun jasa saatos penjualan profésional.

Nagara ékspor urang kaasup Rusia, Koréa Kidul, Britania, Perancis, Jérman, Italia, Kanada, Méksiko,Brazil, Argentina, Chili, Australia, Indonesia, Thailand, Singapura, Arab Saudi, Suriah, Mesir, Tanzania.Kenya jeung nagara séjén. Produk urang bakal sumebar ka sakuliah dunya!

Naha milih kami?

1. Salaku upplier pabrik-langsung, urang ngaleungitkeun margin middleman nawarkeun maneh harga paling kalapa pikeun fasteners kualitas luhur.

2.pabrik urang lulus sertifikasi ISO 9001 jeung AAA .we boga nguji karasa jeung test ketebalan palapis séng pikeun produk galvanized.

3. kalawan kontrol pinuh leuwih produksi jeung logistik, urang ngajamin pangiriman on-waktu malah keur pesenan urgnt.

4.tim rékayasa urang bisa ngaropea faseners ti prototipe pikeun produksi masal, kaasup desain thread unik tur coatings anti korosi.

5.From baja karbon hex bolts ka tinggi-tensile jangkar bolts, kami nyadiakeun solusi hiji-eureun pikeun sakabéh kaperluan fastener Anjeun.

6. Lamun sagala cacad kapanggih, urang gé reship Panggantian dina 3weeks ongkos urang.